Microbial Barrier Testing (ASTM F1608-21)

Microbial Barrier Testing according to ASTM F1608-21 is a scientifically robust method used to evaluate the ability of porous packaging materials to resist microbial penetration. For sterile medical devices, maintaining an effective sterile barrier throughout storage, transportation, and handling is a critical regulatory requirement. At QACS Lab, this testing is performed under strict conditions to provide quantitative data on how well packaging materials prevent microbial ingress (the potential entry of microorganisms into a sterile system which can lead to contamination) supporting manufacturers in demonstrating compliance with international standards.

The ASTM F1608-21 method exposes the test material to a controlled aerosolized microbial challenge and measures the degree to which microorganisms can pass through the material under defined conditions. This performance evaluation is directly aligned with the expectations of ISO 11607-1 and ISO 11607-2, the globally recognized standards for packaging of terminally sterilized medical devices. In addition, the EU Medical Device Regulation (MDR 2017/745) and the FDA Quality System Regulation require manufacturers to validate the microbial barrier function of their sterile barrier systems. Microbial Barrier Testing provides essential data for meeting these obligations.

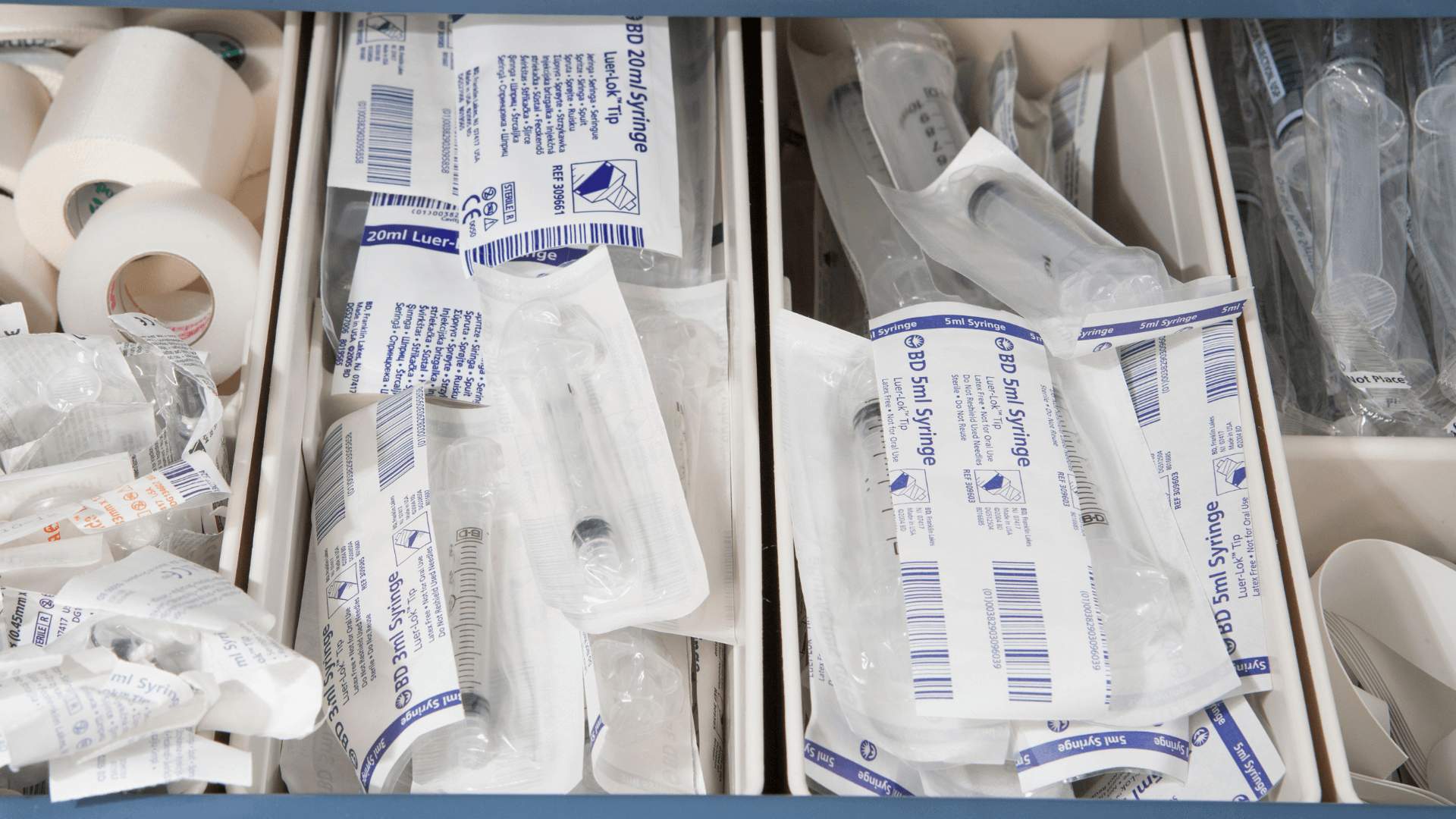

This service is particularly relevant for manufacturers producing sterile medical devices such as surgical instruments, implants, wound-care materials, drapes, sterilization pouches, container systems, filters, and any device intended to maintain sterility until point of use. By assessing the protective capacity of medical-grade papers, nonwoven materials, and multilayer packaging structures, the test supports critical decisions during material selection, design verification, and packaging validation.

At QACS Lab, Microbial Barrier Testing is performed by experienced specialists using validated methodologies and controlled environmental conditions. We provide complete reporting, interpretation of results, and technical guidance to support product development, troubleshooting, and regulatory submissions. Our goal is to help manufacturers ensure packaging robustness, strengthen regulatory compliance, and secure the safe delivery of sterile devices to healthcare professionals and patients.

Contact us for Medical Devices Testing solutions