Packaging Testing for Medical Devices

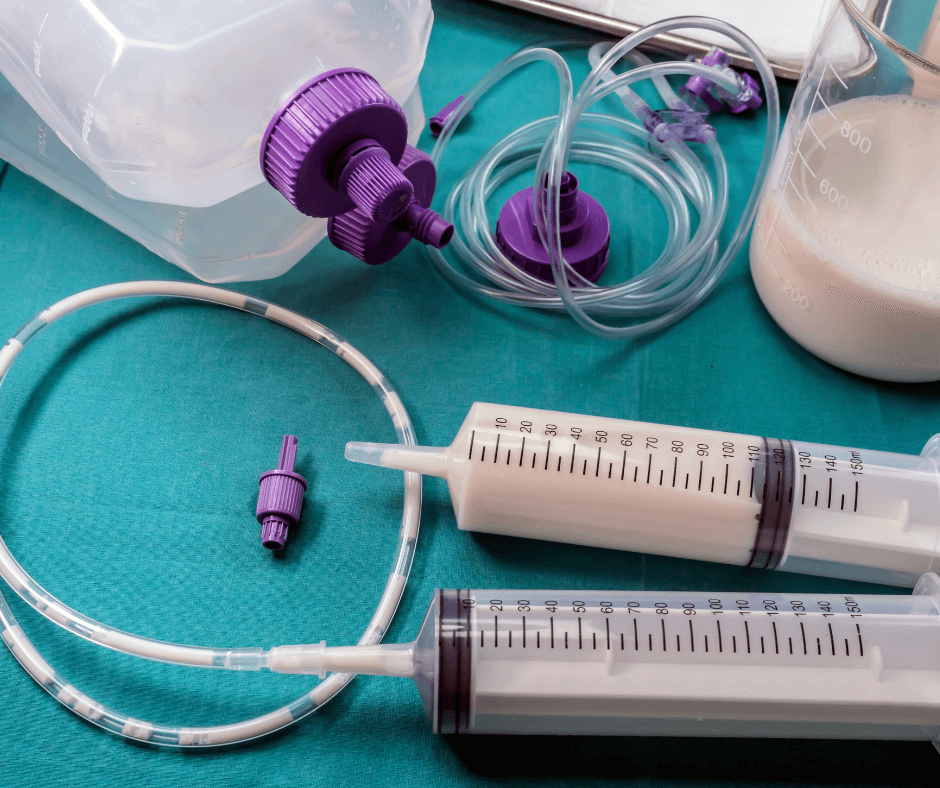

Packaging constitutes a crucial part of all sterile Medical Devices. As part of quality management system, Packaging Testing for Medical Devices is highly regulated with the aim to ensure the safety and the effectiveness of the final products. Packaging of Medical Devices should be safe throughout the product shelf life (from manufacturing process to placing into market).

QACS laboratories provide complete packaging testing services for packaging validation for medical devices according to ISO 11607 (Packaging for terminally sterilized medical devices). Packaging Testing is based on the appropriate category of Medical Devices and is custom-designed by our team of experts to best serve your product’s needs. Check QACS’s Packaging Testing for Medical Devices below:

– Packaging Aging studies (Real and accelerated aging, ASTM F1980)

– Packaging integrity testing (visual inspection, Dye penetration testing, Burst test)

– Packaging physical testing (Oxygen permeability, water permeability test, air permeance)

– Packaging strength testing (Determination of seal strength, seal peel, Creep test, tensile testing)

– Packaging Microbial testing (F1608, F2638)

Finally, our laboratories specialize in Extractables and Leachables studies for medical devices according to ISO 10993 guidance.